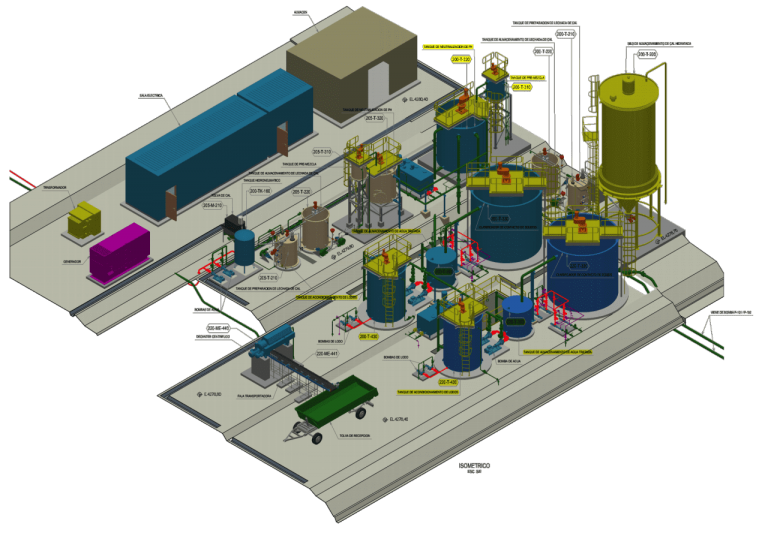

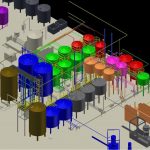

Brida is here to help you determine the most efficient tank design. Our stainless steel workshop is fully equiped to provide high quality tanks that are hard to top. Several food processing, dairy, beverage and chemical companies throughout Peru have a high degree of trust and confidence in the quality and reliability of our stainless steel sanitary tanks.

Our designs include:

- Heating or cooling external jackets – Liquid medium or steam rated

- Suitable insulation and cladding – Sealed SS cladding

- Suitable tank venting size based on several processing factors including cleaning processes

- Tank fittings: removable hygienic CIP sprayballs

- Processing instrumentation can be supplied by our partners

- Load cell systems incorporated in our products

Brida provides processing and storage tanks for several beverage products such as:

- Dairy, chocolate, yogurt and oil

- Fruit juice and drinks

- Bottled water

- Beer, soda & wine

- Soft drinks

We manufacture a wide range of equipment and offer a variety of options to fit the processing needs of our customers, including:

- Customized design and fabricated stainless steel tanks, reactors and vessels

- Sanitary storage tanks

- Workshop or field fabrication capabilities

- Agitation systems designed for customized processes

- Different interior and exterior materials and weld finishes

- Heating and cooling options

- API 620-650

- Sanitary assembly, gaskets with FDA approved materials

- Manholes and fittings

- Single wall, jacketed with or without insulation

- Tank supports & parts (legs, lugs, skirts, saddles and flat pitch)

- Components: sight glasses and lights, CIP systems, no foam inlets, downtubes, thermowells and outlet valves

- Botton tank valves, pneumatic control valves

- Ultrasonic level control

- Mass flow meters

- Other components

- Material: SS304L – SS316L

- Capacity: 500L to 800 80,000L

- Surface finish: Sanitary Ra≤ 0.7um

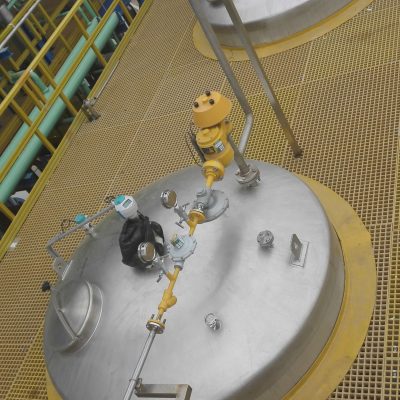

High capacity silos from 50m3 to 300m3

Agitators, cooling jackets, insulation

For milk, oil and more

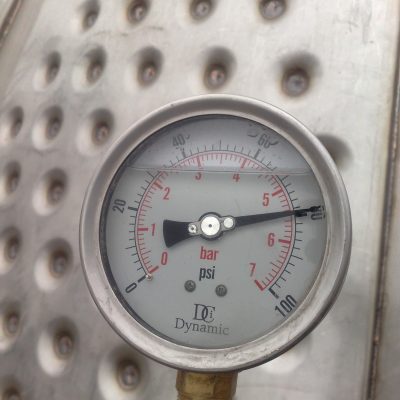

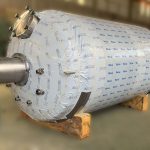

SS high pressure reactors of low and high capacity

Pressure: up to 400psi customized

Mechanical seals, agitators, cooling jackets and insulation

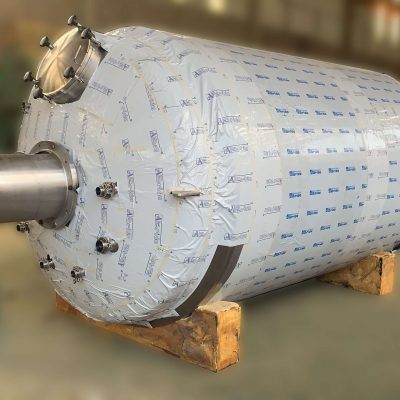

SS high pressure reactors of low and high capacity

Pressure: full vacuum

Mechanical seals, agitators, cooling jackets and insulation

Brida designs and manufactures SS absorption towers

Long vertical column used in industry for absorbing gases

The gas is introduced at the bottom of the column and the absorbing liquid, often water, passes in at the top and falls down agains the counter current of gases. These are also known as scrubers

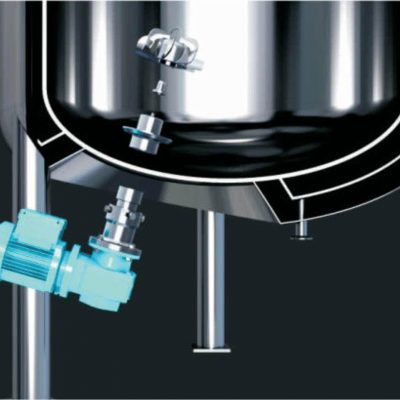

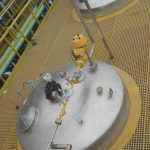

- Mixing agitators

- Emulsifying agitators

- Coating dispersers

- Scraper blade agitators

- Offset turbine agitators

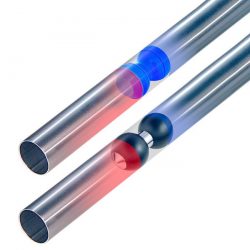

Magnetic tank agitators in stock

Capacity: 1,000L to 80,000L

Magnetic driven agitators are essential to liquid processing for biotechnology, pharmaceutical and food industries due to their hermetic and aseptic design.

Installation of different types of thermal insulation for reactors, piping and equipment:

- Foam insulation

- Fiber glass – Mineral wool

- Cellulose – Natural fibers

- Polystyrene – Polyurethane

- Vermiculite and Perlite – Cementitious foam

- Ethanol distiller

- Solvent distiller

- Pisco distiller

- Other

- Dimpled cooling jackets, body and bottom tanks, pressure working: 100psi for steam and cooling water

- Half pipe jacket, working pressure: up to 400psi

- Spiral tube inside tanks and pillow plate cooling

- Beer fermentators up to 200HL

- Wine fermentators

- Food processing fermentators

- Dairy processing fermentators

- Other

- Ammonium nitrato reactors (explosive mining)

- Mining processing reactors and equipments

- Pulp and cellulose equipments

- Coating dispersers and processing equipments

- Others

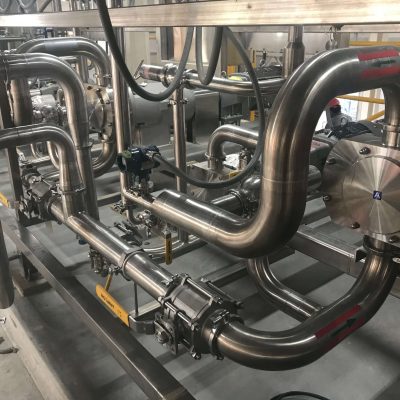

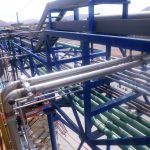

We are capable of installing more than 12,000m of sanitary piping in each project for food industries, from 1/2″Ø to 6″Ø.

- Sanitary pumps, valves, fittings, pipe racks, pipe holder

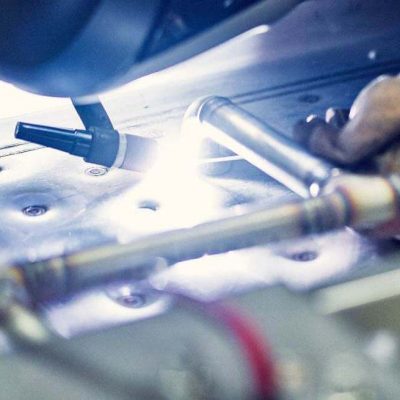

- Pipelines are welded on the inside with Argon chambers

- Sanitary surface finish is less than Ra≤0.5um

A major part of our core business is related with the massive installation of sanitary piping and utilities. We count with the appropriate machines and tools for installation, as well as several welding and cutting equipment, scissor lifts and boom lifts that makes it possible to achieve the most strict time constrains of our customer’s deadlines.

Also, we have a large stock of stainless steel piping and fittings, which guarantee the timely delivery of the projects.

- Dimensions: 1/2″Ø to 24″Ø and more

- Stainless steel sanitary piping ASTM A-270, DIN 11850

- Industrial stainless steel piping

- Piping for utilities such as: steam, condensate, cooling water, hot water, air, gas and more

- HDPE and PVC piping

- Carbon steel pipelines

- Industrial SS pipelines

- HDPE pipelines

- PVC pipelines

- Other

We perform automated orbital TIG welding

Automated pipe cutters

- Pre-assembled in our workshop

- Final assembly in-situ

- Materials: stainless steel, carbon steel with shot blasting epoxy painting

- Capacity: up to 3,000m3

- We count with a complete system for in-situ assembly, such as all-terrain hydraulic cranes and engineered scaffolding

- Welding: TIG – MIG – Tubular, Submerged-arc welding (SAW)

The CIP washing unit is designed for the cleaning of processing tanks and piping in dairy, food, beverage, pharmaceutical and cosmetic industries, minimizing the consumption of water. Cleaning in place (CIP) refers to a method used to clean production facilities and pipelines. The plant is cleaned in circular or continuous processes, without prior disassembly.

CIP tank size: 500L to 20,000L

CIP tank type: Alkaline tank, acid tank, hot water, clean water tank, water recycle tank

Cleaning recycling: single circuit, double circuits, three circuits and four circuits

Fully automated:

– Flow rate auto control

– Temperature auto control

– Auto compensated CIP liquid level

– Auto compensated liquid concentration

– Auto transfer of cleaning liquids

– Auto alarm

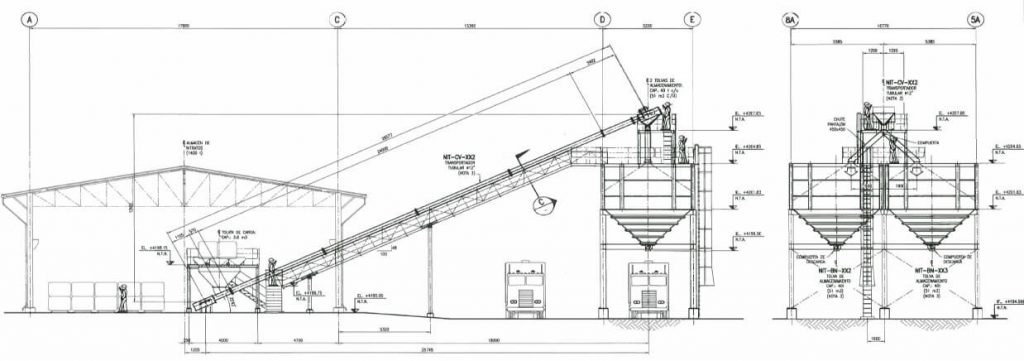

Brida supplies a wide variety of conveyor systems to meet the needs of the automotive, food processing, bottling, pharmaceutical, chemical, cements and mining.

– Material handling

– Food & beverage

– Packaging

– Systems integration

– Accumulation conveyor

– Conveyor system design

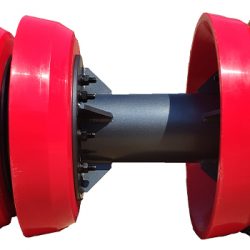

Tube chain conveyors move materials inside a tube pulled by a chain. It offers a convenient way of conveying bulk material from one location to another and also multi-axially. Tube chain conveyors are used for transporting, feeding dosing, distributing and discharging pourable bulk materials.

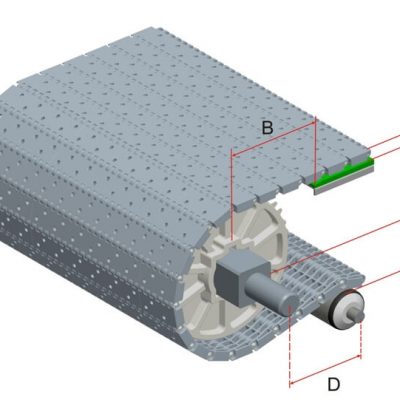

BPM modular conveyor systems and flexible plastic chain conveyors are quick and easy to install. Integrated material flow solutions for assembly systems and automated production and packaging. We offer automated solutions with global presence and industry expertise. Material: PP, PE, Acetal

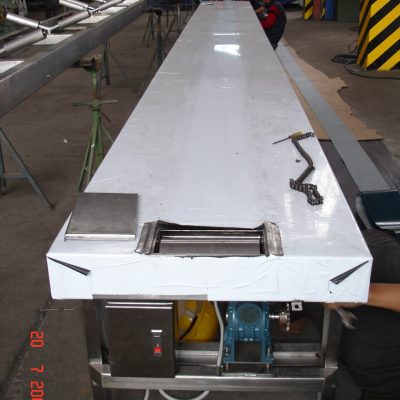

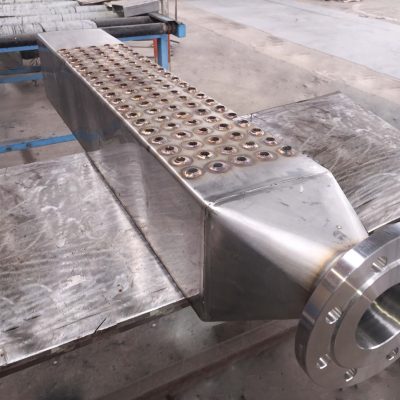

SS tubular screw conveyors offer a variety of solutions for conveying or feeding powdery or granular materials. They are suitable for applications in which any contamination of the material handled has to be strictly avoided and where absolute cleanliness and perfect resistance to corrosion are required.

Belt conveyors made for heavy duty industries: coal, mining, power plants, fertilizers and more. Mainly sanitary belt conveyors for handling bulk food materials of leading suppliers in the industry.

Main products: PVC/PU/PE/silicone/rubber light conveyor belts.

Bucket elevators are used to vertically transport large amounts of bulk material to different heights without creating dust. The height is up to 20m.

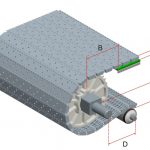

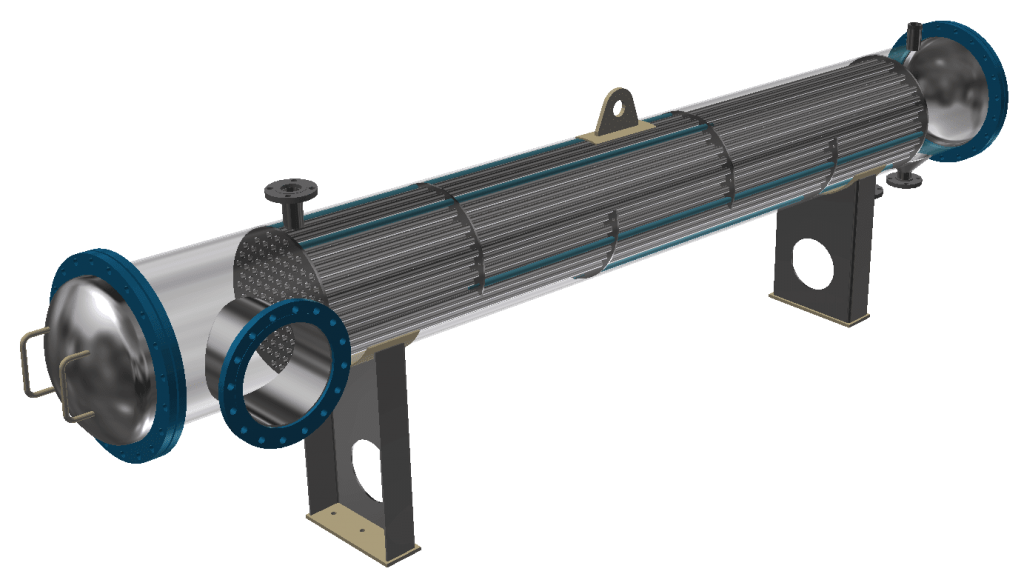

Stainless steel heat exchangers, include shell and tube, brazed plate, heating and cooling coils, plate and frame, embossed and pillow plate. These heat exchangers are custom-made and pre-engineered for industrial & sanitary designs.

Shell & Tube heat exchangers constructed from 304 and 316 Stainless Steel are corrosion resistant and can be built to meet various industrial, pharmaceutical, food, dairy, and beverage requirements.

Plate heat exchangers consist of metal plates sealed with a gasket, welded, or some combination of the two.

Plate heat exchangers are also available on a wide range of plate sizes and configuration.

Pillow or Dimpled plate heat exchangers are designed for compact spaces, highly versatile panels that can be welded, formed, or fitted to meet your exact needs from a variety of materials including steel and stainless steel.

Continuous cookers or heaters are useful in mass production. They are easily disassembled for cleaning and use a high pressure positive displacement pump of 1.5’’ to 4’’ OD.

We manufacture efficient and versatile blending machines for mixing dry powders, granules and viscous pastes homogeneously.

Our mixers are able to deliver outstanding results for mixing due to the innovative designs of the spiral agitators inside of the U-shaped chamber.

– Ribbon (3 types available): different sizes and applications

– Construction material: SS 304L and SS316L sanitary polished

– Feeding & discharging: a variety of feeding & discharging methods can be selected by the customers, pneumatic valve and manual.

– Drive system: drive system by geared motor, cycloidal reducer, worm reduce, belt or chain transmission

– Heating/cooling jacket: jacketed for heating/cooling operation

– Vacuum drying & deaerating: the mixers can be designed for vacuum drying & deaerating for special applications.

– Spray nozzle: liquids can be added into powders by spray nozzles on the top

– Continuous operation: we can supply machines for continuous work when a large capacity per hour is needed for the same material.

– Solid blending & drying equipments

– Capacities: 50L to 2,000L

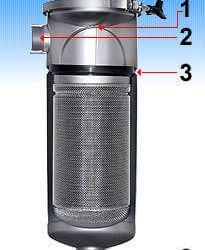

Johnson Filters

Filters are widely used in the auxiliary service for food and industrial processing, chemicals and pharmaceutical industries due to its hygienic design and they are mainly used to filter fluids from pumps and other equipments.

Stainless steel sanitary filters used for filtration of potentially undesirable particles for alientos, easy to clean.

– PTAR waste water filtration systems.

– Straight and Y type angle housing

– PP cartridge filter

– Screw wedge johnson filters

– Vacuum filters

– Sieves for liquids and solids

– Duplex filters

Micro filters using PP/PTFE/Cn-CA cartridge. These filters can get rid of bacteria and dispose exhaust until the gas reaches HIM standards.

Hole diamater: 0.1um, 0.22um, 1.0um, 3.0um, 5.0um and 10um.

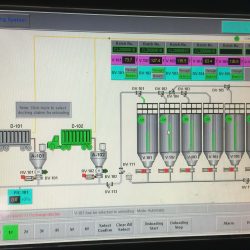

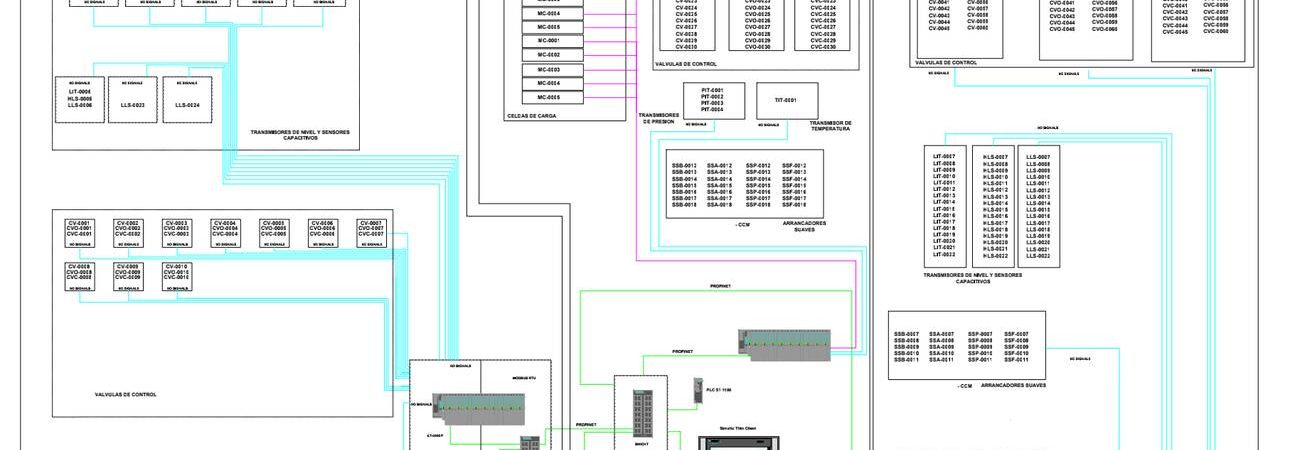

Electricity & PLC Control

Installation of the electric system, lighting and control for industries and processing stations.

Electricity:

– Control centers for engines

– Design and assembly of electric panels

– Installation of bandejas electricas

– Electric wiring

– Grounding system

– Engine testing

– ATEX- explosion proof lighting systems

PLC- Control

– Design of control systems

– Philosophy control

– Wiring

– Control panels

– Commissioning